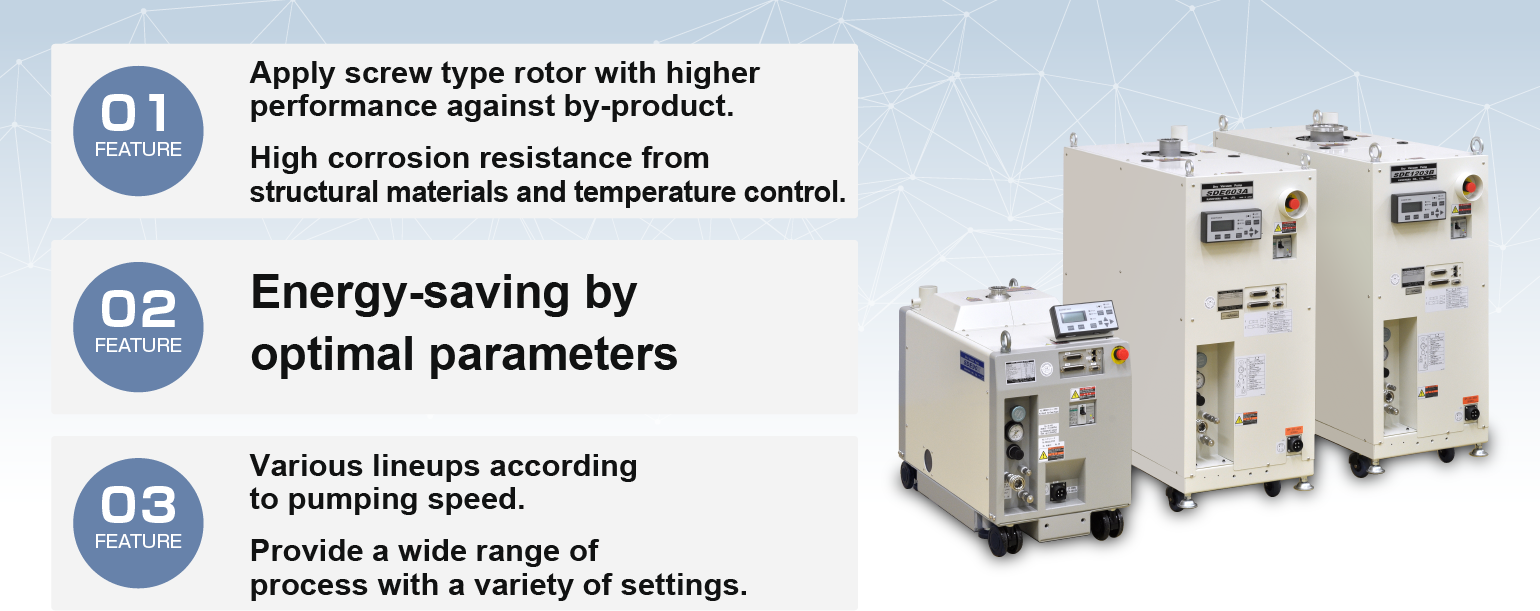

Description

SDE Series

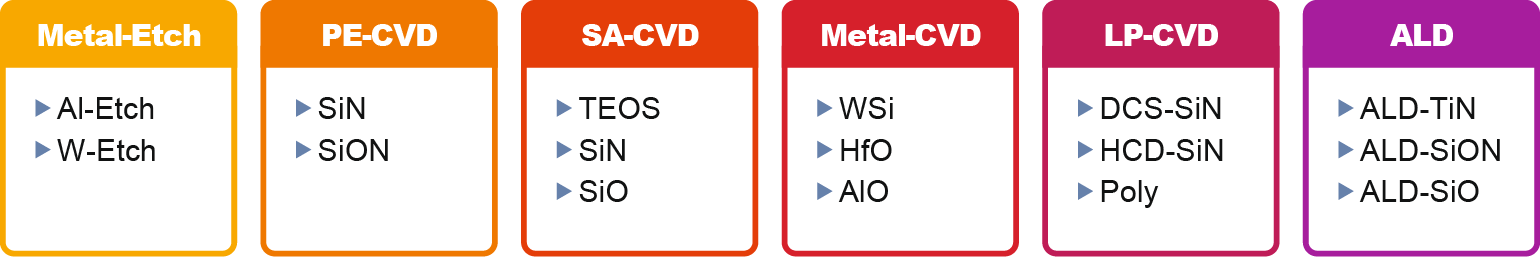

Harsh Process Application Example

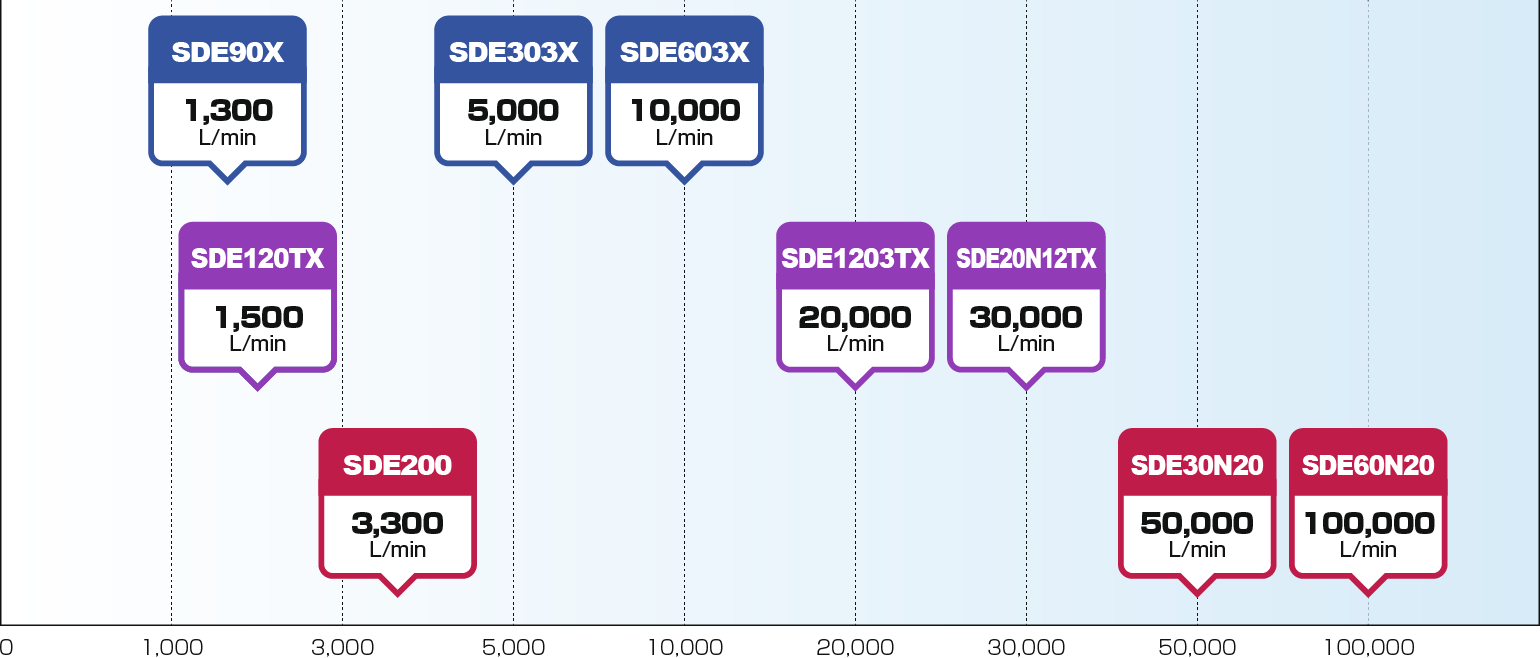

Lineup by Max. Pumping Speed

Max. Pumping Speed[L/min]

Major Products

| Spec. / Products | SDE90X | SDE120TX | SDE200 | SDE303X | SDE603X | SDE1203TX | SDE20N12TX | SDE30N20 | SDE60N20 | |

| Max. pumping speed [L/min] *1 |

1,300 | 1,500 | 3,300 | 5,000 | 10,000 | 20,000 | 30,000 | 50,000 | 100,000 | |

| Ultimate pressure [Pa] *1 |

1.3 | 0.5 | ||||||||

| Supply voltage (50/60Hz) |

3Phase AC200~220V, 380~480V | |||||||||

| Power consumption [kW]*2 | 1.3 | 2.8 | 2.7 | 1.5 | 1.6 | 3.2 | 3.3 | 3.7 | ||

| Dimensions [mm]*3 | L | 690 | 930 | 900 | 1000 | 1000 | 1080 | |||

| W | 370 | 400 | 400 | 450 | 450 | 515 | ||||

| H | 501 | 500 | 905 | 1000 | 950 | 950 | ||||

*1) Without N2 purge. *2) Approx. value at ultimate pressure. *3) Package size.

* Contact us about international standard compliance. Spec. & name of products are subject to change without prior notice. * Contact us about applicable gas.

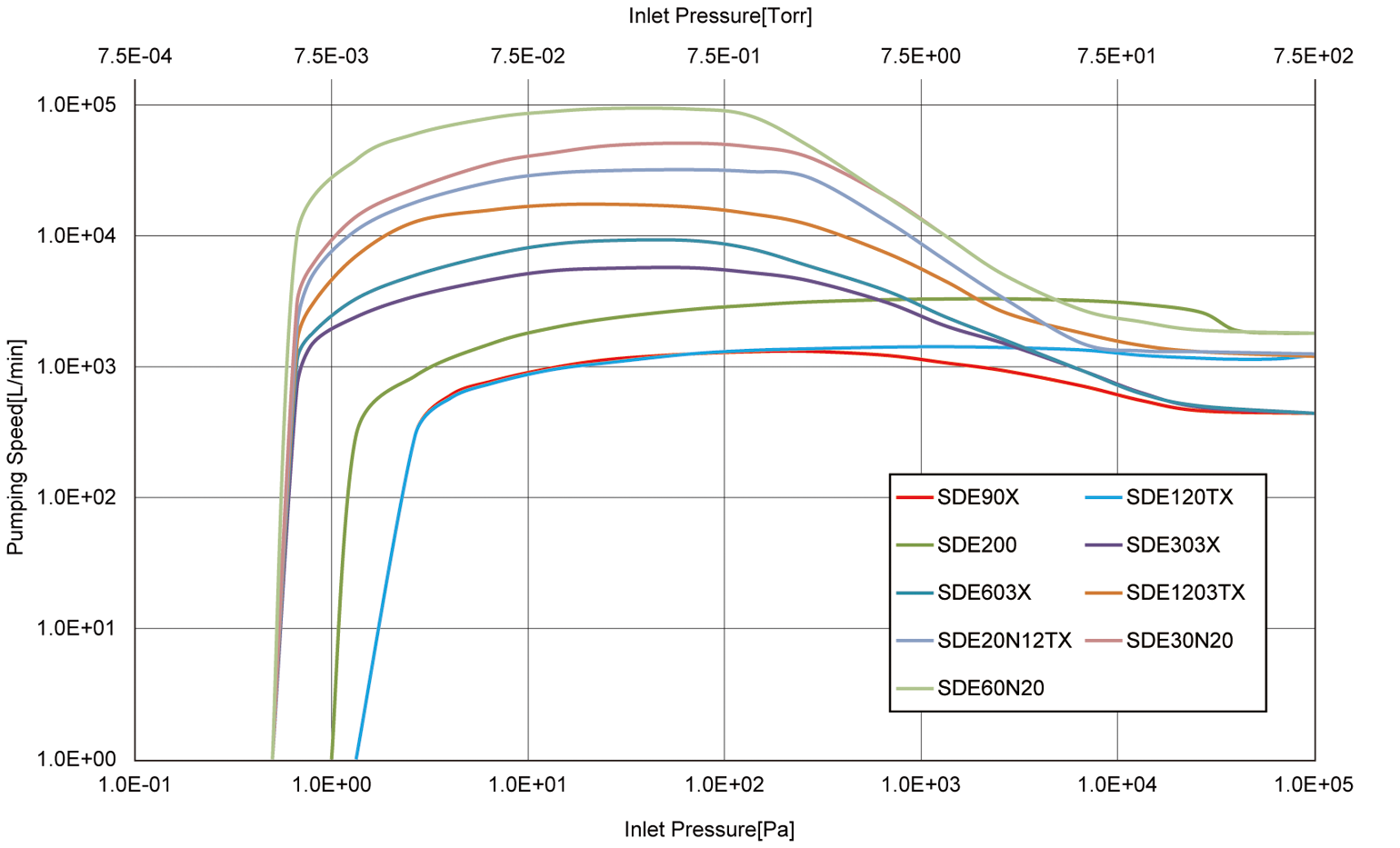

S-P Curve

* S-P curves vary by combination.

Option